Power Quality References

We’re by your side, in every sector where energy efficiency and sustainability are essential

Every day, our clients experience real economic savings and reduced CO₂ emissions thanks to our power quality solutions.

Sectors where EP-X has already made a difference

Large-scale distribution

Large-scale distribution is one of the most energy-intensive sectors. The implementation of the EP-X system for energy savings provides immediate and widespread benefits to this particularly relevant sector, which is widespread throughout the national territory. Not only that: the current structure of the main groups and chains in the GDO sector has allowed us to install EP-X internationally, expanding awareness around the quality of our product throughout Europe.

In a highly competitive sector such as Large-scale distribution, it is essential to be able to offer added value and a message of solidarity and respect for the environment. The improvement of energy efficiency, guaranteed by EP-X and certified at the European level, not only allows companies to achieve energy-saving and emissions-reduction goals, but also becomes a key asset to link to their brand identity, to push competition towards green innovation.

Updated as of January 2026

EP-X installed

kWh saved

kg CO₂ reduced

average efficiency improvement

Success stories

COOP

EP-X

Large-scale distribution

At the beginning of 2013, Novacoop, the company that manages Ipercoop stores in Piedmont, decided to conduct a pilot test with an EP in a store in the city of Turin. The measured efficiency result was positive and led to the installation of other EP-X systems in their stores.

CONAD

EP-X

Large-scale distribution

In 2021, Conad decided to install EP-X 800A devices, achieving significant savings in both energy and operating costs. Given the results, the company has decided to continue using the EP-X system for the next few years at other sites belonging to the cooperative.

BENNET

EP-X

Large-scale distribution

In July 2025, the first 800A EP device was installed at the Bennet supermarket in Sedriano (MI). Over the following six years, a further 31 EP-X devices were installed across Bennet sites in Lombardy, Piedmont and Emilia-Romagna.

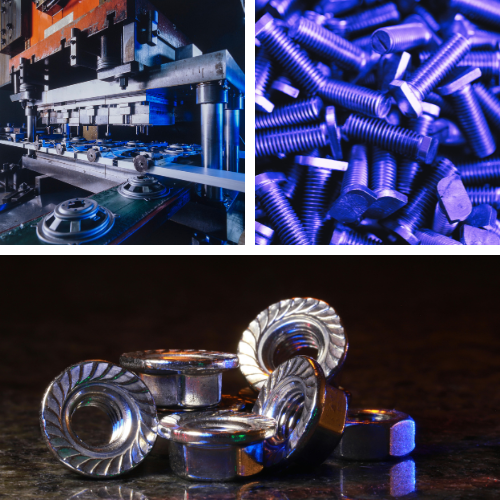

Metalworking industry

Saving and improving industrial energy efficiency are among the main European and national focuses in terms of energy-saving regulations and emissions reduction. Improving energy performance in industrial plants allows for targeted interventions to reduce consumption and emissions in highly energy-intensive businesses.

Energia Europa has already installed EP-X devices in a growing number of leading companies aiming at industrial energy efficiency. As in other sectors, we have received significant recognition, extending installations even outside Europe. This result is possible thanks to the high quality, effectiveness, and reliability of a product based on solid research and development foundations, which can be quickly integrated into a company without modifying existing systems.

Updated as of January 2026

EP-X installed

kWh saved

kg CO₂ reduced

average efficiency improvement

Success stories

FORGITAL GROUP ITALY

EP-X

Metalworking industry

At the beginning of 2021, the customer decided to proceed with the purchase of a first pilot machine for its main Italian production plant in the Veneto region. Given the results produced by this first Ep-X device, Forgital decided to extend the efficiency project to its other plants by installing additional EP-X devices.

SIT ITALY

EP-X

Metalworking industry

In October 2015, the first 1600A EP device was installed in one of their plants. Over the following three months, two more 1000A devices and another 1600A device were installed on other lines in the same plant.

F.LLI MAURI ITALY

EP-X

Metalworking industry

In May 2022, F.lli Mauri installs its first EP-X device at one of its plants in Italy. Given the results achieved, a second 1000A EP-X is installed the following year.

Plastics and rubber industry

The plastics industry represents one of the most favorable sectors for the effectiveness of the EP-X system, in terms of energy efficiency, improvement of energy quality, and reduction of maintenance costs.

The plastics industry is vital for the European economy; producers of plastic raw materials, together with processors, recyclers, and machinery manufacturers, represent a value chain that employs over 1.5 million people in Europe in over 55 thousand companies, most of which are SMEs operating in all European countries, with a total turnover of over 350 billion euros.

Updated as of January 2026

EP-X installed

kWh saved

kg CO₂ reduced

average efficiency improvement

Success stories

Berry Global Group Inc

EP-X

Plastics and rubber industry

Given the company’s objectives in terms of energy efficiency and sustainability, the customer wanted to test a new and effective solution for the efficiency of its production sites, which would allow a return on the investment in a sufficiently short time.

ADAPA Italy Florence

EP-X

Plastics and rubber industry

Operating in a typically energy-intensive sector and using extrusion systems very sensitive to the quality of the power supply, the customer was looking for a solution that, in addition to ensuring a certain energy saving, also improved power quality and therefore helped to reduce downtime and maintenance costs.

STEFANPLAST ITALY

EP-X

Plastics and rubber industry

The customer wanted to test a solution on the main plant that would simultaneously produce both energy savings and improved power quality in order to reduce the maintenance costs of production machinery.

Automation and automotive

The automotive and automation sectors are fundamental pillars of the European industry, contributing to productivity and competitiveness across the entire economy. In this context, Europe stands out for its technological leadership and the presence of many high-profile companies. The main players in these sectors are concentrated mainly in Germany, France, and Italy, but the entire and complex production chain also involves many other European countries.

In this highly energy-intensive industry with continuous production flows, the application of EP-X devices becomes essential to ensure energy optimization and improve power quality, a factor that contributes to the reduction of production downtimes.

Updated as of January 2026

EP-X installed

kWh saved

kg CO₂ reduced

average efficiency improvement

Success stories

SIEMENS AG

EP-X

Automation and automotive

The company’s Head of Global Sustainability was looking for a new efficiency solution to be tested at one of the group’s various sites and then adopted as a standard in the event of positive measured results.

CORNAGLIA GROUP

EP-X

Automation and automotive

As part of an ambitious energy efficiency program aimed at obtaining carbon neutrality in its production chain, the Cornaglia Group wanted to test an innovative solution that would guarantee energy savings and improve power quality.

ODELO

EP-X

Automation and automotive

The company was looking for an energy efficiency solution that would also improve power quality and therefore contribute to the reduction of production downtime.

Food sector

The application areas of the EP-X device in this industry refer to both the food processing and beverage sectors. The units used are generally medium-high power, between 1,000 A and 2,000 A. The food (food and beverages) industry is among the most important industries in Europe in terms of turnover (about €1.2 trillion) and employment (around 4.7 million people, approximately 15% of total manufacturing employment in Europe), as highlighted in the 2018 report by the association FoodDrinkEurope.

It is an industry with nearly 300,000 companies, which has proven over time to be stable, strong, and resilient. Although diverse, its top five segments (bakery and farinaceous products, meat products, dairy industry, beverages, and other food products) account for three-quarters of total turnover and over 80% of companies and employees. Despite variations depending on market and company size, the entire food supply chain in recent years has shown increasing attention to energy efficiency and sustainability.

Updated as of January 2026

EP-X installed

kWh saved

kg CO₂ reduced

average efficiency improvement

Success stories

FINDUS

EP-X

Food sector

The customer was looking for a solution that would allow to obtain further energy efficiency on top of the interventions already carried out on its Italian plants in Latina, and then evaluate its application in the Group’s remaining production sites in Europe.

PERONI BIER

EP-X

Food sector

The customer was looking for an effective and easy-to-apply centralized efficiency solution that could be applicable in all three Italian plants.

BRAZZALE

EP-X

Food sector

The customer wanted to test a further solution as part of a vast global efficiency project aimed at making the company a true international reference in the field for environmental sustainability, achieving “carbon neutrality”.

Hotel & Restaurant

The high energy consumption in the hospitality and catering sector stems from a range of electrical equipment and lighting fixtures, most of which are essential for delivering basic services. These are unavoidable costs that weigh heavily on the budget. Installing EP-X makes it possible to achieve excellent results, as demonstrated by the case studies available on the page.

The variety of business types within the hospitality and catering sector is reflected in a wide range of specific needs. However, what is essential—especially in this sector—is comprehensive consultancy that includes not only the technical data required to size and optimise the EP-X product, but also an overview of the incentives and subsidies available to the hospitality and catering industry, which are particularly crucial at this time.

Updated as of January 2026

EP-X installed

kWh saved

(Kg) Quantità di CO2 recuperata

Efficientamento medio complessivo misurato

Success stories

LOAS

EP-X

HoReCa

As part of a company policy strongly focused on energy efficiency and environmental sustainability, the customer wanted to implement a further efficiency solution that would guarantee a verifiable energy saving and the consequent reduction of CO2 emissions.

GRAND HOTEL UNION

EP-X

HoReCa

Grand Hotel Union is a historic 4-star accommodation in the heart of Ljubljana. Built in 1905 by architect Josip Vancaš in the Art Nouveau style, the construction of the Grand Hotel Union was a great event for the time and over the years has hosted political, film, musical and royal celebrities, including the British Queen. Even today Grand Hotel Union maintains its splendid Slovenian style and character, but at the same time offers the modernity of the largest conference center in Ljubljana, which can accommodate up to 800 guests with a wide range of services and event spaces.

AUTOGRILL

EP-X

HoReCa

The customer was looking for a centralized and efficiency solution, which would guarantee a homogeneous measurable and verifiable result in terms of energy savings and emission reduction; in addition to the efficiency results, the customer highlighted the need to monitor and manage the energy and electrical data of all the sites where the device would be installed.

Logistics and management

Energy savings in the administrative logistics sector have the advantage of being perceived more tangibly by the users of the spaces who receive energy through the EP-X filter. Structures that benefit from our energy-saving solution in this sector experience the environments daily, which may be lacking in other facilities. The direct economic benefit consists of lower energy procurement costs, supplemented by reduced indirect costs due to less maintenance and fewer replacements of electrical equipment and lighting fixtures. In the reported case studies, we can boast particularly satisfying results.

The application areas of the EP-X device primarily concern logistics hubs and administrative centers, with average power ratings between 600 A and 1,600 A. The logistics world in general represents an enormous and strategic sector of the EU economy, accounting for about 5% of the economy's added value and generating employment for over 11 million workers.

Updated as of January

EP-X installed

kWh saved

(Kg) Quantità di CO2 recuperata

Efficientamento medio complessivo misurato

Success stories

KYMP TALO

EP-X

Logistics and management

The customer was looking for a suitable solution to generate further energy efficiency on already largely efficient sites, and then, if successful, continue the applications on a series of public buildings managed by the municipality.

DB SCHENKER

EP-X

Logistics and management

The client was looking for an effective energy efficiency solution for its logistics sites in Finland, in addition to the interventions already carried out to achieve its efficiency and sustainability goals.

ITALGAS

EP-X

Logistics and management

Within the refurbishing process of some of its own buildings used as corporate offices, the customer was looking for a centralized energy efficiency solution that would be effective in terms of energy savings and compatible with the company policies of return on the investment.