Interview with Gabriele Paltrinieri, Chief Marketing Officer of Energia Europa S.p.A.

Are you dealing with energy losses, harmonics, or unplanned downtime? We can support you with a dedicated analysis of your electrical system.

You can:

- fill out the form on our website to be contacted by our team

- call us directly at +39 0445 510156

Power Quality has become a strategic factor for energy-intensive companies: it directly affects operational continuity, efficiency, and long-term investments. To understand how this topic is evolving and which solutions are truly effective today, we interviewed Gabriele Paltrinieri, Chief Marketing Officer of Energia Europa.

The interview combines technical insights and direct questions, helping companies understand what really happens inside their electrical systems and how to intervene using next-generation technologies.

1. In energy-intensive industrial plants, Power Quality is often discussed in a rather superficial way. Which critical issues are still underestimated today?

Even today, technical management teams often lack reliable data to detect Power Quality phenomena that impact production efficiency and energy waste. Companies usually have accurate data on energy consumption — useful for energy audits and sustainability reporting — but they rarely measure the factors that determine poor Power Quality in terms of disturbances and losses.

Gabriele Paltrinieri

This lack of in-depth measurement prevents many companies from identifying the real causes of inefficiencies, which are not related to consumption itself but to electrical disturbances.

2. In some of your previous talks, you highlighted the role of distortion reactive power as a frequently overlooked factor in complex systems. In which industrial contexts does this become truly critical?

Today, most electrical systems are dominated by distorting loads such as inverters, switching power supplies, LED lighting, IT equipment, and photovoltaic systems. In distorted environments, both active and reactive power contain a strong distortion component caused by current and voltage harmonics.

This leads to losses, malfunctions, and an increased risk of production downtime. Moreover, capacitive reactive power — now very widespread — cannot be compensated using traditional systems, which have become ineffective in modern installations. New-generation solutions are required to compensate both inductive and capacitive reactive energy in real time.

Gabriele Paltrinieri

3. Which technical criteria guide the choice of the most suitable solution to improve Power Quality in a complex electrical system?

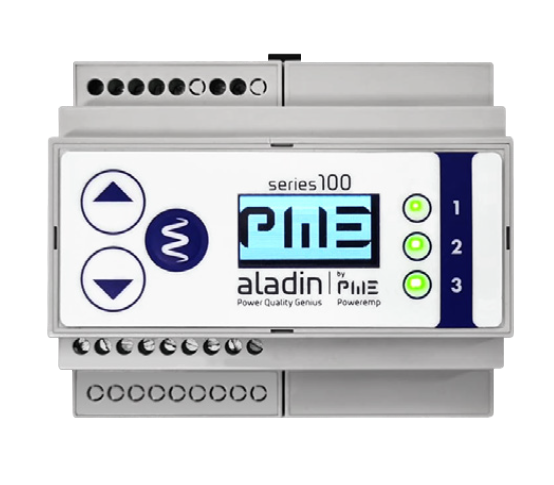

The starting point is having reliable data, which is not easy to obtain. This is why, together with the University of Florence, we developed a portable, high-sampling-rate power network analyzer called Aladin, designed to accurately measure Power Quality phenomena.

In most cases, one week of measurements is enough to determine the most appropriate solution. If we detect only reactive power issues — both inductive and capacitive — we propose our base solution PQ-VAR, which compensates in real time and balances currents. When significant harmonic components are also present, we recommend more advanced versions that add harmonic mitigation to the core functions.

Gabriele Paltrinieri

Aladin: advanced power network diagnostic system for fast and reliable Power Quality analysis

Would you like to understand what is really happening in your electrical system? We can carry out a dedicated measurement campaign using high-precision instruments.

You can:

- fill out the form to request a Power Quality analysis

- call us at +39 0445 510156

4. Harmonics are among the most common causes of inefficiency and malfunctions. How is the approach to their mitigation evolving?

In systems dominated by distorting loads, harmonic mitigation is essential to prevent losses and operating errors. Our new-generation solutions are designed to intervene extremely quickly, even in distorted and capacitive environments, reacting in less than 5 milliseconds.

Gabriele Paltrinieri

5. How much does phase imbalance really affect system performance, and why is active balancing now so important?

During our measurement campaigns, we frequently detect significant imbalances between the three phases. This can seriously compromise the correct operation of machinery, which is why the balancing function is so highly valued by our customers.

Gabriele Paltrinieri

6. In which applications does fast compensation make the difference in preventing downtime or micro-interruptions?

Highly distorted systems with strong load variability — such as data centers, photovoltaic plants, and automated production lines — represent a real challenge for traditional solutions, which often cannot keep up with their dynamic behavior.

Our electronic solutions intervene in less than 5 milliseconds, ensuring stability even under highly variable operating conditions.

Gabriele Paltrinieri

7. From a total cost of ownership perspective, how much can Power Quality affect operating costs?

Investing in Power Quality is always a smart decision, because the costs associated with disturbances, losses, equipment failures, and downtime can be extremely high. A study conducted across 16 European Union countries shows that poor Power Quality can impact up to 4% of company turnover.

In highly energy-intensive and sensitive sectors — such as plastics, pharmaceuticals, and automation — an effective solution can pay for itself very quickly.

Gabriele Paltrinieri

8. What value does collaboration with academia bring to Energia Europa?

It is essential. Together with the University of Florence, we launched the Smart Energy Lab, a joint laboratory dedicated to Power Quality research. This collaboration has led to further developments of our EP-X solution, the portable diagnostic analyzer, and the creation of a new Power Quality-dedicated product line.

We are also developing new solutions to address voltage issues and micro-interruptions, which are currently in the testing phase.

Gabriele Paltrinieri

9. Looking ahead, what developments do you foresee in Power Quality for energy-intensive industries?

Energy efficiency in general, and Power Quality in particular, represent the next frontier of the energy transition. Shifting from fossil fuels to renewables must be accompanied by improved Power Quality, reducing waste, inefficiencies, and industrial costs. The cleanest energy is the energy that is not consumed.

Gabriele Paltrinieri

Would you like to improve operational continuity and reduce energy losses? We can analyze your system and propose a tailored solution.

You can:

- fill out the contact form on our website

- call us at +39 0445 510156