Reading time: 6 minutes

When the company’s electrical network affects costs: what we discovered in companies like Stefanplast

Do you want to improve the efficiency of your electrical systems without interrupting production?

Talk to an Energia Europa expert: Tel: +39.0445.510156

Or fill out the contact form.

For many Italian companies, energy savings in businesses are no longer just an opportunity: they are a strategic necessity.

Rising energy prices, system complexity and the constant pursuit of efficiency are putting pressure on both technical departments and management.

Companies often focus on final energy consumption, but overlook what happens inside their electrical systems:

imbalances, harmonics, abnormal absorption and invisible micro-interruptions that impact energy bills and production continuity.

That is why addressing Power Quality is the first step in identifying waste, losses and anomalies that traditional meters do not detect.

Where to start to achieve real and measurable energy savings in companies

Reducing energy costs is not just about “using less energy”: it requires improving the health of the internal electrical network.

The most effective approach follows three key steps.

1. Analyzing how the company consumes energy

Energy-intensive machinery, heavy start-ups and discontinuous production lines: every electrical system has its own unique profile.

Initial mapping is essential to understand where action is needed.

2. Identifying invisible disturbances and inefficiencies

Harmonics, imbalances, high neutral currents and absorption peaks are not visible to the naked eye, yet they heavily affect energy bills and the lifespan of machinery.

3. Acting with devices that stabilize the electrical network

This is where EP-X comes into play: a solution designed to reduce energy losses, stabilize the network and improve the performance of all connected equipment.

Energy costs have become a structural issue

Every company produces “dirty” energy without realizing it.

Network distortions not only increase consumption, but also generate disturbances and losses that slow down production.

- heavier-than-necessary start-ups

- machines consuming more energy to achieve the same output

- shorter lifespan of electronic components

- electrical vibrations that reduce production quality

These phenomena are particularly evident in companies operating presses,

ovens, robotic systems and inverter-driven machinery.

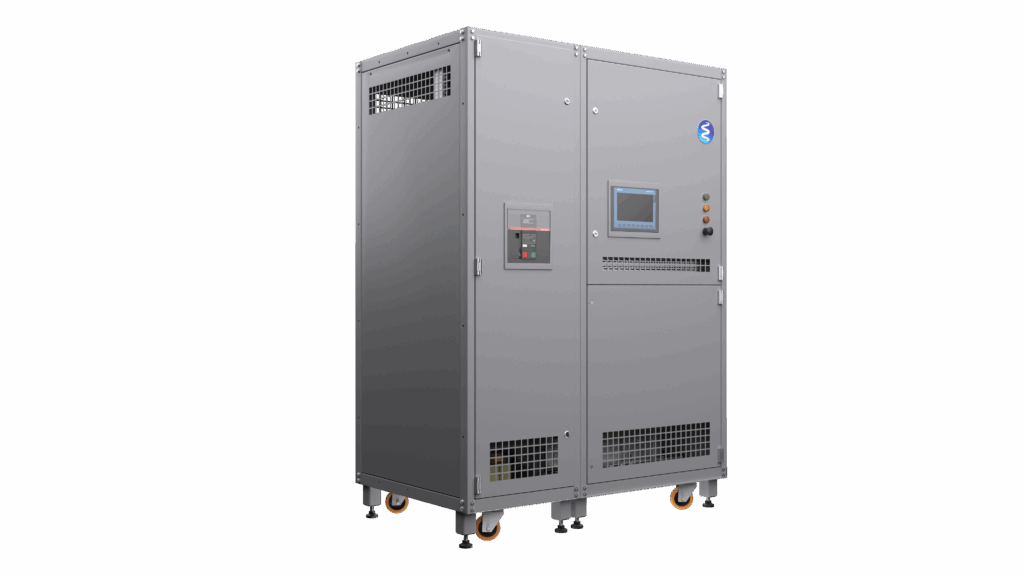

How the EP-X Power Quality device helps companies save energy

The EP-X Power Quality device is designed to stabilize company electrical systems and reduce unnecessary energy consumption.

It acts on:

- absorption peaks

- overheating and phase imbalances

- harmonics

- abnormal machine absorption

- electrical stress on sensitive components

Measurable benefits include:

- reduced electricity consumption

- greater efficiency of motors, presses and automated lines

- fewer machine downtimes

- improved production continuity

- extended equipment lifespan

EP-X is already installed in hundreds of Italian and international companies

and represents a fast-to-implement investment with a quick return.

Would you like to understand if EP-X is suitable for your systems?

Call us: Tel: +39.0445.510156

Or fill out the contact form.

Stefanplast reduced electricity consumption by approximately 6% thanks to EP-X

Stefanplast is a leading Italian company in the production of plastic household items, with highly energy-intensive production lines and a machinery park consisting of electric and hydraulic presses.

The initial challenge

- significant absorption peaks

- electrical instability due to continuous load variations

- inefficiencies in older production lines

- electrical stress on sensitive equipment

Despite optimizing production processes, energy consumption remained high.

Energia Europa’s intervention

- analysis of energy absorption profiles

- monitoring of power quality

- identification of areas with the highest deviations

- installation of EP-X on the main production lines

Results achieved

During the first months of monitoring, Stefanplast recorded

energy savings of approximately 6%

on the electricity consumption of the involved production lines,

without modifying production cycles or interrupting operations.

This reduction was accompanied by a more stable electrical network,

fewer anomalies and an overall increase in press efficiency.

Read the full Stefanplast case study

How much can a company really save?

- energy-intensive plants gain the greatest benefits

- lines with multiple inverter-driven machines show reduced losses

- processes with frequent start-ups improve significantly

- electrical systems become more stable and efficient

The greatest advantage is that savings do not come from reducing production, but from eliminating invisible energy waste.

What a company can do immediately to save energy

- analyze energy absorption profiles

- check for network distortions

- evaluate the installation of EP-X

- assess the residual lifespan of stressed equipment

- request specialized technical consulting

FAQ

How much can EP-X reduce energy consumption?

It depends on the system, but in most cases savings range between 3% and 6% and are measurable.

Does installation require production downtime?

Yes, but all operations can be completed within a few hours.

Is maintenance required?

Minimal: periodic checks are sufficient.

Would you like to understand how much your company can save?

Call us: Tel: +39.0445.510156

Or fill out the contact form.